In the ever-evolving landscape of modern architecture and design, every element plays a vital role in creating functional yet aesthetically pleasing spaces. Among these integral components is the often-overlooked de rocking raised access floor. This innovative solution not only enhances the efficiency of building infrastructure but also provides a versatile foundation for our increasingly technology-driven environments. As we delve into the world of raised access flooring, we will explore its myriad benefits, applications, and the unique way it transforms both commercial and residential interiors into harmonized realms of practicality and style. Whether you’re an architect, designer, or simply someone interested in the intricacies of contemporary building solutions, understanding the significance of de rocking raised access floors is essential in appreciating how they contribute to the fluidity and dynamism of our living and working spaces.

Table of Contents

- The Evolution of Raised Access Floors: Understanding De Rocking Technology

- Key Benefits of De Rocking Raised Access Floors in Modern Workspaces

- Installation Insights for Optimizing Your De Rocking Floor System

- Maintenance Best Practices for Long-Lasting Performance and Safety

- Q&A

- Future Outlook

The Evolution of Raised Access Floors: Understanding De Rocking Technology

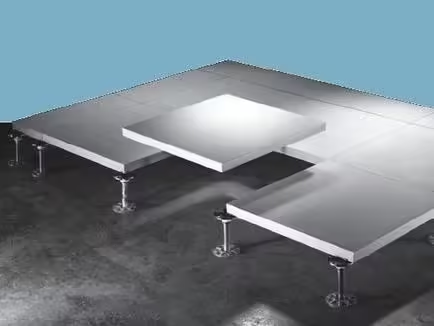

The concept of raised access floors has undergone significant transformation over the years, reflecting the evolving needs of modern architecture and technology. One of the most fascinating advancements in this field is the introduction of de rocking technology, which specifically addresses stability and adaptability concerns. As more offices and data centers move towards open layouts and high-density installations, traditional approaches to flooring systems can struggle to maintain structural integrity. The incorporation of de rocking features helps to mitigate issues such as vibration, movement, and uneven floor surfaces, providing a solid foundation for sensitive equipment and ensuring a comfortable work environment.

These innovative systems are designed with enhanced support structures and damping mechanisms that absorb shocks and vibrations, promoting an optimized work area. Key benefits of de rocking raised access floors include:

- Improved stability: Minimizes unwanted movement over time.

- Enhanced safety: Prevents injury risks caused by floor instability.

- Easy maintenance: Facilitates access to cabling and utilities without compromising structural integrity.

- Customization: Allows for tailored solutions based on specific environmental and operational needs.

To visualize the advantages more clearly, consider the following table that compares traditional raised access floors to systems utilizing de rocking technology:

| Feature | Traditional Raised Floors | De Rocking Raised Floors |

|---|---|---|

| Vibration Resistance | Limited | High |

| Load Capacity | Moderate | Enhanced |

| Maintenance Access | Standard | Effortless |

| Installation Flexibility | Fixed | Adaptable |

Key Benefits of De Rocking Raised Access Floors in Modern Workspaces

De rocking raised access floors offer a multitude of advantages that contribute to the overall efficiency and functionality of modern workspaces. With their unique design, these flooring systems facilitate enhanced cable management, allowing for seamless integration of electrical and data cabling below the surface. This accessibility not only minimizes clutter but also enables quick adaptations to changing technology needs. Additionally, the adjustable heights of these floors provide flexibility for various configurations, accommodating different layouts and designs with ease.

The innovative features of de rocking raised access floors also significantly improve air distribution and thermal comfort in office environments. By elevating the floor, these systems create a space for effective airflow, enhancing HVAC efficiency. This leads to improved air quality, reducing the risk of staff discomfort and increasing productivity. Moreover, they are designed with noise reduction in mind, helping to create a more productive work atmosphere by minimizing sound transmission between levels.

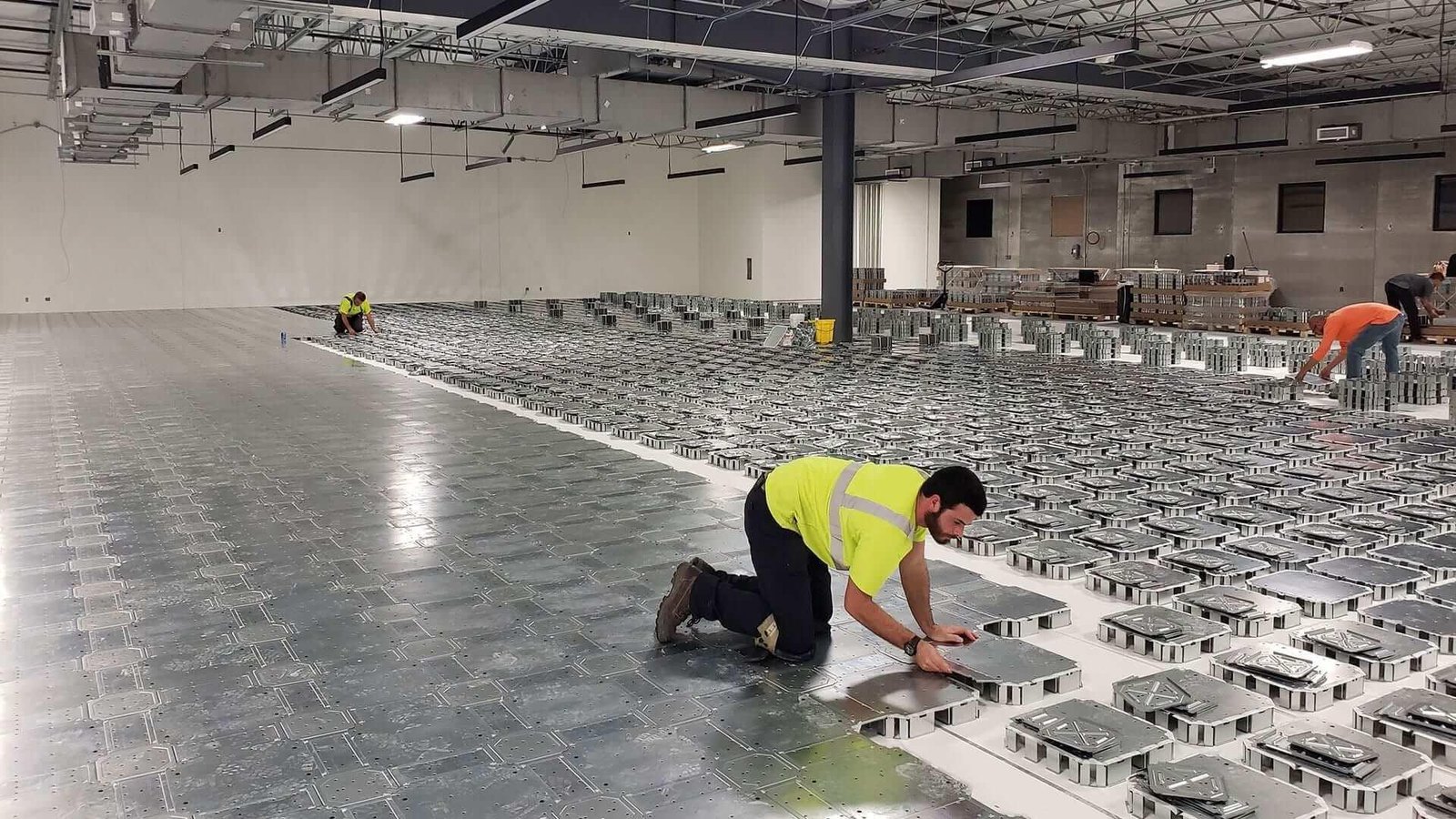

Installation Insights for Optimizing Your De Rocking Floor System

When embarking on the journey of installing a de rocking raised access floor, understanding the foundational aspects can significantly impact the overall effectiveness of your system. Ensure you start with a solid subfloor as this will serve as the bedrock for your raised access floor. An uneven or weak foundation can lead to complications such as unwanted vibrations or shifting. Furthermore, take into consideration the load requirements for your space. We recommend employing a professional to calculate these metrics to prevent overloading components, which can lead to premature wear and failure.

Incorporating advanced installation techniques can further improve the performance of your de rocking system. Strategically place acoustic matting between the base and floor panels to mitigate sound transmission and enhance stability. Additional tips include:

- Provide ample expansion joints to accommodate natural movement.

- Incorporate locking mechanisms on panels for an added layer of security and stability.

- Utilize adjustable pedestals for managing height variations efficiently.

The following table summarizes essential materials required for an effective installation:

| Material | Purpose |

|---|---|

| Acoustic Matting | Sound dampening and stability enhancement |

| Leveling Pedestals | Height adjustments for even surfaces |

| Locking System | Secures panels in place |

Maintenance Best Practices for Long-Lasting Performance and Safety

To ensure optimal performance and enhance safety, regular maintenance of a rocking raised access floor is essential. Begin by conducting thorough inspections to identify any signs of wear or damage. For effective maintenance, incorporate the following practices into your routine:

- Regular Cleaning: Vacuum and mop the floor tiles to remove dust and debris, preventing buildup that could affect stability.

- Check Joints and Seals: Inspect joints for gaps or misalignments that may compromise the integrity of the floor.

- Test Floor Stability: Periodically test the flooring for abnormal movement or rattling sounds, indicating possible issues.

- Inspect Underfloor Systems: Access and check underfloor wiring and piping to ensure they’re not causing floor deformation.

In addition to routine checks, implementing a preventive maintenance schedule can significantly extend the life of your flooring system. Keeping detailed records allows you to track the condition and maintenance history of the floor. Consider developing a simple maintenance table to monitor these activities, such as:

| Date | Maintenance Activity | Next Scheduled Check |

|---|---|---|

| 01/01/2023 | Full Inspection and Cleaning | 07/01/2023 |

| 07/01/2023 | Joint and Seal Check | 01/01/2024 |

| 01/01/2024 | Stability Test | 07/01/2024 |

By diligently adhering to these maintenance practices, you can ensure that your rocking raised access floor remains a safe, functional, and durable component of your environment.

Q&A

Q&A: Understanding De Rocking Raised Access Floors

Q1: What exactly is a de rocking raised access floor?

A1: A de rocking raised access floor is an innovative flooring system that minimizes the movement and instability commonly associated with traditional raised access floors. Its design features stabilizing elements that help maintain a level surface, ensuring that the floor does not sway or rock underfoot. This stability is particularly useful in environments where precise equipment is used or where safety is paramount.

Q2: How does a de rocking raised access floor differ from standard raised access floors?

A2: Standard raised access floors typically rely on support pedestals that can sometimes lead to slight rocking or vibration. In contrast, de rocking raised access floors incorporate advanced engineering techniques and materials that enhance structural integrity, significantly reducing any potential movement. This makes them ideal for sensitive environments, such as data centers or laboratories, where even minor vibrations can disrupt operations.

Q3: What are the key benefits of using a de rocking raised access floor?

A3: The key benefits of a de rocking raised access floor include enhanced stability, improved safety, and superior adaptability for technological infrastructure. Users can benefit from easier installation and maintenance, as well as increased flexibility for future changes in layout or equipment. Additionally, the reduced movement might lead to a longer lifespan of electronic devices and machinery by minimizing unnecessary stress.

Q4: Where are de rocking raised access floors typically utilized?

A4: De rocking raised access floors are commonly used in environments that demand high precision and reliability. This includes data centers, telecom rooms, control rooms, and laboratories. They are also beneficial in commercial office spaces looking to create flexible work environments that can adapt to changing technological needs.

Q5: Are there any downsides to consider when choosing a de rocking raised access floor?

A5: While de rocking raised access floors offer numerous advantages, potential downsides can include a generally higher initial investment compared to standard raised access flooring systems. Additionally, the installation process may require specialized expertise to ensure proper integration with building infrastructure. It’s essential to weigh these factors against the long-term benefits and stability they provide.

Q6: How can one ensure the proper maintenance of a de rocking raised access floor?

A6: Maintenance of a de rocking raised access floor typically involves regular inspections to check for any signs of wear or damage. It’s important to ensure that all access panels are secured and that support pedestals remain stable. Routine cleaning and the removal of debris from the floor void can also help maintain airflow and prevent any potential tripping hazards. Engaging with professionals familiar with the system can provide insights and assistance, ensuring longevity and performance.

Q7: What should one look for when selecting a de rocking raised access floor system?

A7: When selecting a de rocking raised access floor, consider factors such as load capacity, material durability, ease of installation, and the manufacturer’s reputation. It’s also beneficial to inquire about customization options and compatibility with existing infrastructure. Requesting case studies or references from past installations can provide a clearer picture of performance and reliability in real-world applications.

Conclusion:

De rocking raised access floors represent a sophisticated solution for modern building needs, blending stability and adaptability. As industries evolve and technology requirements shift, these systems stand out for their reliability and innovative design, making them a smart investment for the future.

Future Outlook

the de rocking raised access floor stands as a testament to innovation in design and functionality. Its ability to combine aesthetics with practical benefits offers a seamless solution for modern architectural challenges. As environments evolve, the need for adaptable flooring systems becomes increasingly vital, and this revolutionary product embodies that versatility. Whether in bustling office spaces, sophisticated data centers, or expansive retail venues, the de rocking raised access floor not only enhances connectivity and performance but also provides the user with a sense of stability and ease. As we forge ahead into a future where flexibility and efficiency reign supreme, this technology will undoubtedly play a pivotal role in shaping dynamic spaces that meet the demands of tomorrow. With every step taken on these innovative surfaces, we are reminded of the balance between form and function—an equilibrium that will continue to inspire design practices for years to come.