In the ever-evolving landscape of modern architecture and interior design, functionality and aesthetics must walk hand in hand. Enter the realm of steel raised access floor panels—a quintessential innovation that elevates both form and function. As buildings grow taller and technologies advance, the need for versatile spaces that accommodate a myriad of utilities becomes paramount. These unassuming yet powerful flooring systems are not just a structural necessity; they are the unsung heroes behind seamless cable management, climate control, and flexible office layouts. In this article, we will explore the dynamics of steel raised access floor panels, unveiling their myriad benefits, applications, and the role they play in shaping the environments of tomorrow. Join us as we lift the lid on this essential component that quietly supports the architectural tapestry of our daily lives.

Table of Contents

- Understanding the Materials and Design of Steel Raised Access Floor Panels

- Key Benefits of Implementing Steel Raised Access Floors in Modern Workspaces

- Installation Best Practices for Optimal Performance of Raised Access Floors

- Maintenance Strategies to Enhance the Longevity of Steel Raised Access Floor Systems

- Q&A

- To Conclude

Understanding the Materials and Design of Steel Raised Access Floor Panels

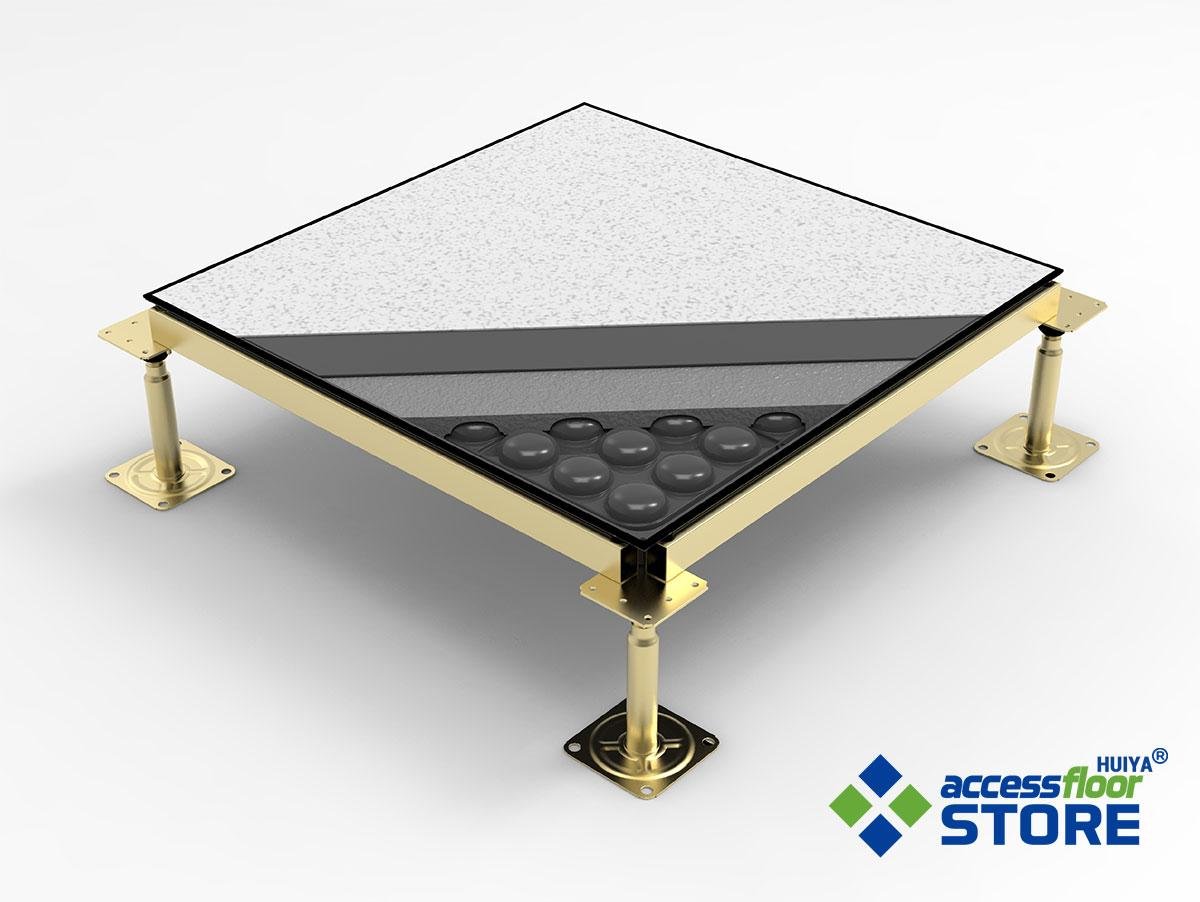

Steel raised access floor panels are pivotal in modern architectural and commercial designs, offering both functionality and versatility. Crafted primarily from high-strength steel, these panels are designed to support substantial loads while providing easy access to the utilities and wiring beneath the floor. The materials used are combined with a robust core, often made from materials such as calcium sulfate or honeycomb paper, which further enhances their durability and resilience to wear and tear. Notably, the surface finishes might vary from sleek powder coatings to textured finishes, allowing designers to choose aesthetics that align with the overall decor.

Each panel is meticulously engineered to ensure stability and resistance to environmental factors. These panels come in various heights and load-bearing capacities, making them suitable for diverse applications, from data centers to office spaces. To better understand their capabilities, consider the following attributes:

- Load Capacity: Capacity can range from 1,000 lbs to over 2,500 lbs per panel.

- Panel Size: Standard sizes typically include 24”x24” and 30”x30”.

- Height Variations: Panels can be adjusted between 3” to 48” in height.

Additionally, the options available for surface treatment can enhance the functionality while aligning with design goals. A table summarizing key features is as follows:

| Features | Description |

|---|---|

| Material | High-strength steel |

| Core Type | Calcium sulfate / Honeycomb |

| Weight | Varies by thickness; typically 22-30 lbs per panel |

| Finishes | Powder-coated, carpeted, or anti-static |

Key Benefits of Implementing Steel Raised Access Floors in Modern Workspaces

Incorporating steel raised access floors in modern workspaces offers a multitude of advantages that enhance both functionality and aesthetics. Flexibility is one of the most significant benefits, allowing businesses to easily reconfigure their layouts as needs change. This adaptability supports dynamic work environments where collaboration is key. Another crucial aspect is the improved airflow management these systems provide. By enabling efficient cabling and ventilation layouts beneath the flooring, companies can maintain optimal climate control while reducing the risk of overheating equipment.

Moreover, steel raised access floors are known for their durability and longevity, setting them apart from traditional flooring options. These floors are resistant to wear and tear, capable of sustaining heavy loads without compromising their structural integrity. Additionally, the reduced maintenance costs associated with steel access floors translate into significant savings over time for businesses. They offer a sleek and modern aesthetic that not only elevates the style of any workspace but also contributes to a cleaner and more organized environment. This combination of style and practicality creates a compelling case for the adoption of raised access flooring in contemporary office settings.

Installation Best Practices for Optimal Performance of Raised Access Floors

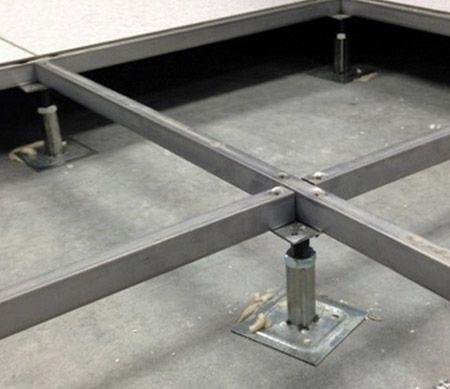

To achieve optimal performance when installing steel raised access floor panels, start by assessing the space where these panels will be placed. Ensuring a robust foundation is critical; the subfloor must be level and structurally sound. A thorough examination can help identify uneven surfaces or potential obstructions that might hinder the panels’ functionality. Utilizing a laser level or a straightedge can provide precise measurements, ensuring that all panels sit flush with one another and avoid any future complications.

Once the foundation is prepared, focus on the layout and the arrangement of the floor panels. If possible, distribute the load evenly to minimize stress on individual panels. Use the following best practices during installation:

- Plan panel placement based on cable management and access needs.

- Employ a grid system for easier modifications and adjustments.

- Secure support pedestals to prevent movement over time.

Additionally, consider integrating underfloor air distribution systems to enhance overall air circulation. The table below highlights the advantages of proper installation:

| Advantage | Description |

|---|---|

| Improved Accessibility | Facilitates easy access to cabling and utilities below the floor. |

| Enhanced Airflow | Optimizes HVAC systems by allowing better airflow dynamics. |

| Future Flexibility | Allows for easy reconfiguration of office spaces as needs change. |

Maintenance Strategies to Enhance the Longevity of Steel Raised Access Floor Systems

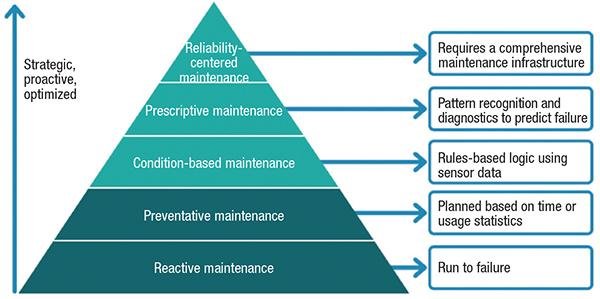

To ensure that steel raised access floor systems continue to perform optimally and maintain their aesthetic appeal, implementing a proactive maintenance approach is essential. Regular inspections can help identify signs of wear, damage, or misalignment early on. It’s crucial to consider the following practices:

- Routine Cleaning: Regularly remove dust and debris from the panels and understructure to prevent buildup.

- Inspection of Panels: Check for signs of corrosion or physical damage, and replace any compromised panels immediately.

- Fluid Management: Address leaks or spills promptly to prevent damage to the flooring and underlying components.

Additionally, establishing a comprehensive maintenance schedule can further enhance the longevity of these systems. By systematically addressing maintenance tasks, facilities can mitigate potential issues and maintain a safe environment. Consider the following maintenance timeline:

| Frequency | Maintenance Task |

|---|---|

| Monthly | Dust and debris removal |

| Quarterly | Visual inspection for damage |

| Annually | Professional assessment and deep cleaning |

Q&A

Q&A on Steel Raised Access Floor Panels

Q: What exactly are steel raised access floor panels?

A: Steel raised access floor panels are modular flooring systems that create a space between the subfloor and the finished floor surface. They consist of steel panels that can be easily lifted to access the space underneath, which is often used for electrical wiring, HVAC systems, and other infrastructure.

Q: Why would someone choose steel over other materials for raised access floor panels?

A: Steel offers unmatched durability and strength, making it ideal for high-traffic environments. It resists corrosion and can support heavy loads, ensuring longevity. Additionally, steel panels can provide enhanced fire resistance compared to other materials, contributing to overall safety.

Q: What are the main benefits of using raised access flooring in commercial spaces?

A: Raised access flooring provides flexibility in design and functionality. It allows for easy adjustments to electrical and networking systems without major renovations. The airflow beneath the panels can improve climate control in tech-heavy environments, making it a popular choice for data centers and office buildings.

Q: Are there any downsides to steel raised access floor panels?

A: While steel panels are robust, they can be more expensive initially compared to other materials like wood or plastic. Moreover, installation may require specialized labor to ensure that the panels are aligned and supported correctly. Additionally, if not properly maintained, any spills or leaks can lead to issues beneath the panels.

Q: How easy is it to install or modify raised access floor systems?

A: Installation can be straightforward for experienced contractors, as the panels typically fit into a grid of pedestals. Modifications are also relatively simple; existing panels can be removed or replaced as needed to accommodate changes in wiring or cooling systems. This adaptability is one of the main appeals of raised access flooring.

Q: Who commonly uses steel raised access floor panels?

A: Industries that require extensive cabling and infrastructure, such as IT firms, telecommunications companies, and financial institutions, frequently utilize steel raised access floor systems. They are also popular in environments like laboratories, healthcare facilities, and even modern office spaces where aesthetic and functional flexibility is key.

Q: How do I maintain a raised access floor system?

A: Maintaining a raised access floor system involves regular inspections of the panels and pedestals for wear and tear. Keeping the area beneath the panels clean and free of debris is essential to ensure airflow and prevent overheating of electrical systems. It’s also wise to address any water leaks immediately to mitigate potential damage.

Q: Are there eco-friendly options when it comes to raised access flooring?

A: Yes, some manufacturers offer eco-friendly raised access floor panels made from recycled materials or those that have low environmental impact during production. Additionally, opting for modular systems ensures that panels can be reused or repurposed, minimizing waste in the long term.

Q: Can raised access floor systems be customized?

A: Absolutely! Steel raised access floors come in various sizes, colors, and finishes. You can tailor them to suit your specific design needs, achieving both functionality and aesthetic appeal in your space.

To Conclude

In the ever-evolving landscape of modern architecture and construction, steel raised access floor panels emerge as a quintessential solution for both functionality and innovation. Their ability to accommodate changing technology needs while optimizing space is a testament to human ingenuity and adaptability. As we reflect on the myriad benefits they offer—from improved air circulation to enhanced cable management—it becomes clear that these panels are not merely a construction choice but a strategic investment in the future of efficient design. Whether you are renovating a commercial space or planning a cutting-edge facility, embracing the potential of steel raised access floor panels may well pave the way toward a more organized, responsive, and resilient workspace. In a world where agility and flexibility are paramount, these panels stand as a sturdy foundation for the endeavors to come.