In the ever-evolving landscape of modern architecture and design, the choices we make in materials often echo the rhythms of functionality and innovation. Galvanized steel grating raised floors have emerged as a hallmark of versatility, seamlessly marrying durability with an aesthetic appeal that meets the demands of contemporary spaces. Whether in commercial settings, industrial facilities, or high-tech environments, these floors offer a robust solution for maximizing both utility and style. As we delve into the features, benefits, and applications of galvanized steel grating raised floors, we uncover how this cutting-edge option not only supports the weight of technology but also elevates the very foundation of our workspaces. Join us as we explore the myriad ways this ingenious flooring system is reshaping the way we build, design, and interact with our environments.

Table of Contents

- Exploring the Benefits of Galvanized Steel Grating in Raised Floor Systems

- Durability and Corrosion Resistance: Key Advantages of Galvanized Steel

- Design Considerations for Optimal Performance and Aesthetic Appeal

- Maintenance Tips to Ensure Longevity of Galvanized Steel Grating Floors

- Q&A

- In Conclusion

Exploring the Benefits of Galvanized Steel Grating in Raised Floor Systems

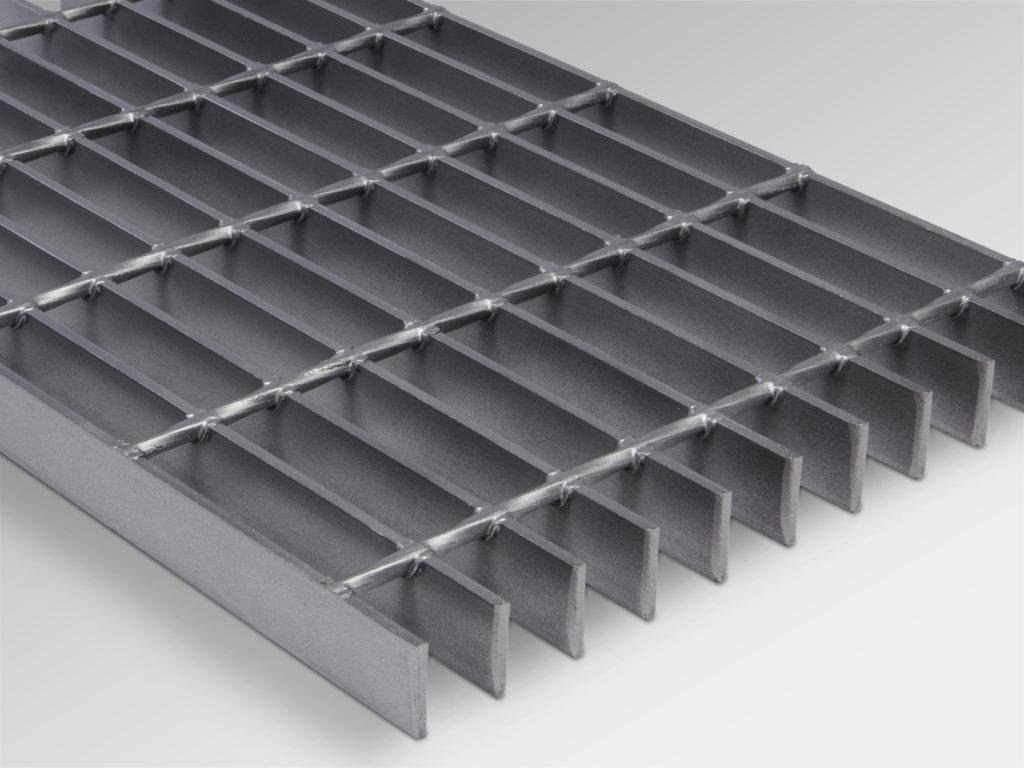

Galvanized steel grating is a game changer in the design and efficiency of raised floor systems. One of its most significant advantages is its durability. The galvanization process provides a protective zinc coating that shields the steel from corrosion and rust, extending the life of the floor system, especially in environments with high humidity or exposure to chemicals. Furthermore, the structural integrity of galvanized steel ensures that it can withstand heavy loads while maintaining its shape over time, making it suitable for various applications, from data centers to industrial facilities.

In addition to durability, the non-slip surface of galvanized steel grating enhances safety in workplaces. This feature is particularly important in high-traffic areas where slipping hazards can lead to accidents. The grating design allows for excellent drainage, preventing water accumulation and minimizing the risk of slips and falls. Moreover, the open grid pattern ensures enhanced airflow and access to underfloor systems, facilitating efficient cooling and easier maintenance. With its long-lasting properties and effective safety measures, using galvanized steel grating in raised floor systems is a smart choice for modern construction needs.

Durability and Corrosion Resistance: Key Advantages of Galvanized Steel

Galvanized steel stands out as a premier choice in construction and design, particularly for raised flooring systems, due to its exceptional durability and corrosion resistance. This steel undergoes a meticulous process of hot-dip galvanization, where a protective zinc coating is applied to the steel’s surface. As a result, it serves as a formidable barrier against moisture, air, and other corrosive elements that could lead to deterioration. The longevity of galvanized steel grating ensures that maintenance costs are significantly reduced over time, making it a cost-effective option for both commercial and industrial applications.

Furthermore, the intrinsic properties of galvanized steel provide numerous advantages in various environments. It exhibits superior mechanical strength and an ability to withstand heavy loads, making it ideal for high-traffic areas. The combination of durability and resistance to rust translates into reliable performance, even in harsh conditions, such as coastal or industrial settings. Consider the following key benefits:

- Longevity: Extended lifespan reduces the need for replacements.

- Low Maintenance: Minimal upkeep due to corrosion-resistant properties.

- Cost Efficiency: Initial investment offsets long-term savings.

- Environmental Impact: Recyclable material that contributes to sustainable practices.

Design Considerations for Optimal Performance and Aesthetic Appeal

When designing raised floors using galvanized steel grating, achieving a balance between performance and aesthetics is crucial. Durability is a fundamental aspect to consider; galvanized steel not only provides strength but also resists corrosion, making it a preferred choice in environments with varying humidity levels. Additionally, load-bearing capacity should be evaluated to ensure the grating can withstand the operational demands of the space. Essential design parameters include:

- Spacing between grating panels for optimal airflow

- Thickness of the grating to enhance weight distribution

- Finish options to boost appearance while maintaining slip resistance

Another key factor is the harmonious integration of the floor into the overall design of the facility. Aesthetically pleasing elements can be incorporated, such as color finishes or custom patterns, that not only elevate the look but also serve functional purposes, like enhancing visibility and safety. Moreover, a thoughtful layout can contribute to an open feel and improved lighting throughout a space. A comparison of common grating designs can highlight their distinct features:

| Grating Type | Applications | Aesthetic Features |

|---|---|---|

| Standard Grating | Industrial, Warehouses | Minimalist Look, Functional |

| Decorative Grating | Retail, Offices | Custom Patterns, Color Options |

| Heavy-Duty Grating | Heavy Machinery, Loading Docks | Sturdy Appearance, Rugged Design |

Maintenance Tips to Ensure Longevity of Galvanized Steel Grating Floors

To ensure the longevity of your galvanized steel grating floors, regular maintenance is essential. Start by conducting visual inspections to identify any signs of wear or damage, such as rust spots or loose grates. Preventive measures include:

- Regularly cleaning the grating surfaces to remove debris and prevent corrosion.

- Applying protective coatings periodically to enhance rust resistance.

- Ensuring proper drainage systems are in place to avoid water accumulation.

In addition to routine inspections, consider implementing a maintenance schedule that includes periodic tightenings of the fastening systems. This helps to keep the grates securely in place and mitigate movement that could lead to structural issues. Key practices for an effective maintenance routine include:

- Establishing a cleaning schedule based on foot traffic and environmental factors.

- Utilizing non-corrosive cleaning agents to preserve the integrity of the galvanization.

- Documenting maintenance actions to track the condition over time.

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Monthly |

| Cleaning | Weekly |

| Coating Application | Annually |

Q&A

Q&A: Understanding Galvanized Steel Grating Raised Floors

Q1: What is a galvanized steel grating raised floor?

A1: A galvanized steel grating raised floor is a modular flooring system that consists of panels made from galvanized steel, typically designed for commercial and industrial environments. The surface is often composed of grating—an array of open spaces and crossbars—that allows for effective ventilation, cable management, and drainage. The galvanization process protects the steel against corrosion, thus enhancing durability.

Q2: What are the primary benefits of using galvanized steel grating in raised flooring?

A2: The primary benefits include durability and longevity due to its corrosion-resistant properties, reduced weight compared to solid steel options, and enhanced airflow which helps maintain optimal temperatures in data centers and server rooms. Additionally, its openness allows easy access to electrical and mechanical systems below the floor, promoting efficient maintenance.

Q3: In what type of environments is galvanized steel grating preferred?

A3: Galvanized steel grating raised floors are particularly preferred in environments requiring high durability and moisture resistance, such as manufacturing plants, data centers, and warehouses. They are also ideal in areas where accidental spills may occur, as the grating can allow liquids to drain away easily.

Q4: Can galvanized steel grating raised floors support heavy loads?

A4: Yes, galvanized steel grating raised floors are specifically designed to support significant weight loads. The design and material provide exceptional strength, enabling them to accommodate heavy equipment and machinery common in industrial settings. However, it’s essential to consult load specifications to ensure suitability for particular applications.

Q5: How does installation compare to other raised floor systems?

A5: Installation of galvanized steel grating raised floors is generally straightforward, involving a grid of pedestal supports that the panels rest on. Since the system is modular, panels can be quickly replaced or adjusted as needed. This contrasts with heavier or solid flooring solutions which may require more complex installation processes.

Q6: Are there any downsides to galvanized steel grating floors?

A6: While galvanized steel grating floors offer many advantages, they might have a few downsides. For instance, their open design may not provide the same level of sound insulation as solid flooring. Additionally, the surface can feel cold or hard underfoot, which may be a consideration for comfort in workplaces designed for extended human use.

Q7: How do you maintain galvanized steel grating raised floors?

A7: Maintenance for galvanized steel grating raised floors is primarily about routine cleaning and inspections. The galvanized finish requires minimal upkeep, but it’s essential to keep the grating free of debris and contaminants. Regularly checking for any signs of wear or damage will help ensure the floor maintains its integrity over time.

Q8: Is there a difference between galvanized and other types of steel grating?

A8: Yes, the main difference lies in the protective coating. Galvanized steel features a zinc coating that guards against rust and corrosion, which is particularly beneficial in humid or corrosive environments. Other types of steel grating may include stainless steel, which also offers corrosion resistance but is generally more expensive. The choice often depends on the specific application requirements and environmental factors.

Q9: What customization options are available for galvanized steel grating raised floors?

A9: Customization options for galvanized steel grating raised floors can include various panel sizes, load ratings, and finishes. You can also choose different styles of grating patterns depending on your aesthetic preferences and functional needs, such as slip resistance or aesthetic appeal.

Q10: Where can one purchase galvanized steel grating raised floor systems?

A10: Galvanized steel grating raised floor systems can be purchased from specialized flooring suppliers, industrial hardware stores, or manufacturers that focus on modular flooring systems. Online suppliers often provide detailed specifications and may also offer customized solutions tailored to specific project needs.

—

This blend of questions and answers aims to clarify the role and advantages of galvanized steel grating raised floors for readers in a neutral tone, enhancing their understanding of this versatile flooring option.

In Conclusion

the use of galvanized steel grating raised floors is a testament to the blend of functionality and innovation in modern architectural design. As industries increasingly prioritize durability and efficiency, this flooring solution stands out as a reliable choice that promises both strength and aesthetic appeal. Its ability to support heavy loads while allowing for effective air circulation makes it an invaluable asset in diverse environments—ranging from data centers to commercial spaces. As we move forward, the enduring qualities of galvanized steel grating will likely continue to shape our approach to functional design, marrying utility with structural integrity. Whether you’re considering an upgrade for your workspace or exploring new construction options, the benefits of this versatile flooring deserve thoughtful consideration. Embrace the future of flooring with galvanized steel grating—a decision grounded in practicality that paves the way for endless possibilities.