In the ever-evolving landscape of modern architecture and interior design, flexibility and functionality have become paramount. Amidst the push for innovative solutions that accommodate technology and enhance efficiency, the steel raised access floor emerges as a silent yet pivotal player. This ingenious structural component offers a dynamic foundation for a plethora of applications, from corporate offices to data centers, all while allowing for seamless adaptability in the face of changing demands. With its unique blend of durability and design, the steel raised access floor redefines conventional flooring, elevating both functionality and aesthetic appeal. As we delve into the nuances of this versatile system, we’ll explore its myriad benefits, applications, and the role it plays in creating spaces that are as practical as they are stylish.

Table of Contents

- The Versatility of Steel Raised Access Floors in Modern Infrastructure

- Essential Design Considerations for Optimal Performance

- Navigating Installation Challenges and Best Practices

- Maintenance Tips for Longevity and Efficiency

- Q&A

- Final Thoughts

The Versatility of Steel Raised Access Floors in Modern Infrastructure

Steel raised access floors offer a remarkable blend of functionality and aesthetic flexibility that caters to the evolving demands of modern infrastructure. Ideal for a variety of applications, including commercial offices, data centers, and educational institutions, these systems facilitate an organized and efficient environment. Their design not only supports high load capacities but also allows for easy access to plumbing, electrical wiring, and HVAC systems, promoting efficient maintenance and adaptability. The ability to customize floor panels, finishes, and heights ensures that each installation can be tailored to fit specific architectural and operational needs, enhancing the overall user experience.

The versatility of raised access flooring extends beyond practicality; it also significantly influences the interior design of spaces. By creating an accessible void underneath, architects and designers can better manage cable management and cooling systems, contributing to an organized and streamlined look. Furthermore, the incorporation of materials like carpet tiles and vinyl can enhance acoustics and aesthetics, allowing for seamless integration into various styles of decor. Key benefits include:

- Enhanced flexibility: Quick reconfiguration of spaces to meet changing requirements.

- Improved airflow: Facilitating better climate control via underfloor air distribution.

- Easy maintenance: Simplifying access to essential building systems without disrupting daily operations.

| Feature | Description |

|---|---|

| Load Capacity | Supports heavy equipment and foot traffic effectively. |

| Customizability | Available in various heights, materials, and finishes. |

Essential Design Considerations for Optimal Performance

When designing a steel raised access floor, several key factors must be considered to ensure optimal performance and longevity. First and foremost, the load capacity of the panels plays a crucial role, as it determines how much weight the floor can support without compromising its integrity. Additionally, height adjustment is critical; the space under the floor should accommodate all necessary cabling, pipes, and equipment while allowing for easy access for maintenance. Another important consideration is the finish material, which can affect both aesthetics and functionality. Common materials include vinyl, carpet, or tiles, each offering different levels of durability and ease of cleaning.

Furthermore, the design layout of the grid system must be meticulously planned to facilitate airflow and cable management. This setup not only enhances the efficiency of the floor space but also contributes to a seamless operational flow. It’s equally important to think about acoustic properties; sound absorption features can enhance the working environment, making it quieter and more productive. In the table below, we summarize essential design elements and their impacts on performance:

| Design Element | Impact on Performance |

|---|---|

| Load Capacity | Ensures safety and reliability under heavy loads. |

| Height Adjustment | Facilitates efficient space utilization and maintenance access. |

| Finish Material | Affects durability, maintenance, and visual appeal. |

| Grid Layout | Enhances airflow and optimizes cable routing. |

| Acoustic Properties | Reduces noise levels, improving workplace comfort. |

Navigating Installation Challenges and Best Practices

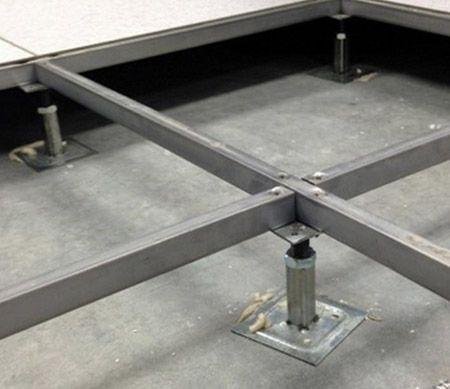

When considering the implementation of a steel raised access floor, addressing installation challenges proactively can significantly streamline the process. Firstly, ensure that you have a well-defined layout plan before beginning any physical work. This should include a comprehensive inventory of all components needed, such as panels, pedestals, and finishes. Regular communication with the installation team is essential to identify potential issues, such as subfloor irregularities or obstacles that may arise, enabling you to adapt quickly. Here are some best practices to keep in mind:

- Conduct a thorough site assessment to identify potential obstacles.

- Establish clear communication among all team members involved in the installation.

- Utilize proper tools and techniques tailored for raised flooring systems.

- Adhere to safety protocols to prevent accidents and ensure a smooth operation.

Additionally, careful planning for system integration can alleviate some of the complexities often associated with raised flooring installations. Mapping out electrical and HVAC systems that will run beneath the floor can help avoid costly modifications later on. Use the following guidelines to ensure effective installation:

| Installation Aspect | Considerations |

|---|---|

| Access Points | Strategically position access points for ease of maintenance. |

| Load Bearing | Verify that the subfloor can support the anticipated load. |

| Finish Selection | Choose finishes that are durable and easy to replace if needed. |

Maintenance Tips for Longevity and Efficiency

To ensure the longevity and efficiency of your steel raised access floor, regular maintenance is essential. Start by conducting routine inspections to identify any signs of wear, damage, or misalignment. Check for loose tiles and ensure that the floor panels are securely fastened. Dust accumulation can also affect airflow and reduce overall efficiency, so make it a habit to clean the surface on a regular basis. Use a mild detergent and soft cloth to avoid scratching the steel finish.

In addition to visual and surface maintenance, it’s crucial to monitor the overall environmental conditions. Humidity levels should be maintained within optimal ranges to prevent moisture damage. Consider utilizing a flooring audit schedule to track conditions and maintenance over time. Incorporating a simple table to summarize critical maintenance tasks can also facilitate effective planning:

| Task | Frequency |

|---|---|

| Visual Inspection | Monthly |

| Surface Cleaning | Weekly |

| Humidity Check | Bi-Annually |

| Comprehensive Audit | Annually |

Q&A

Q&A: Exploring Steel Raised Access Floors

Q: What is a steel raised access floor?

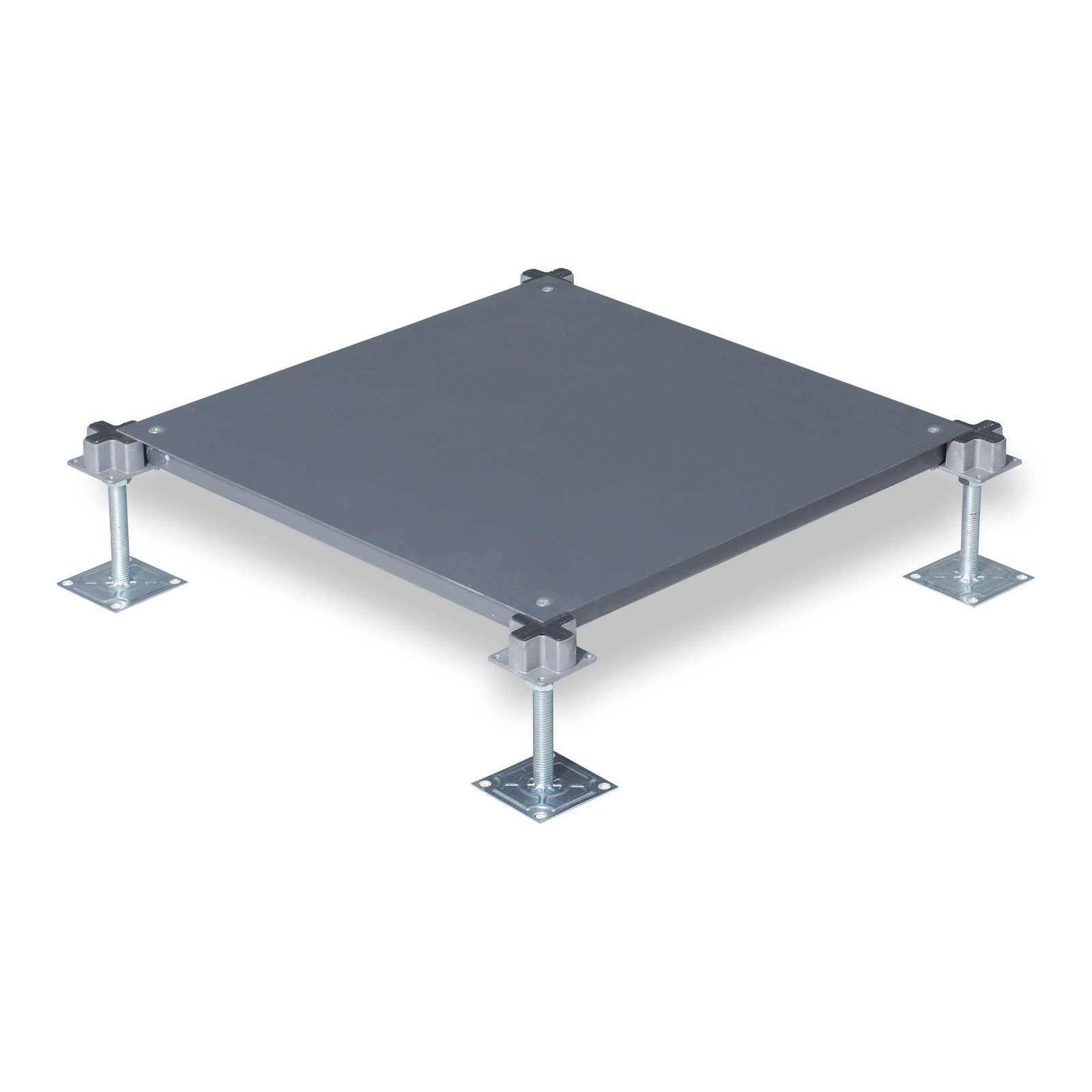

A: A steel raised access floor is an elevated flooring system that creates a hidden space between the structural floor and the finished floor. This system uses a network of panels that are supported by pedestals, allowing for easy access to electrical wiring, plumbing, and HVAC systems beneath.

Q: What are the main components of a steel raised access floor system?

A: The primary components include steel floor panels, pedestals, stringers, and support frames. The panels are typically made of sheet metal filled with a core material like honeycomb or mineral, ensuring strength and stability while providing lightweight characteristics.

Q: What are the benefits of installing a steel raised access floor?

A: There are many advantages, including improved flexibility for office layouts, ease of maintenance for business infrastructure, enhanced air circulation, and protection of mechanical systems from dust and debris. It also allows for quick changes in technology without major renovations.

Q: Where are steel raised access floors commonly used?

A: These systems are widely used in data centers, commercial office spaces, laboratories, and areas that require frequent changes in technology. They are particularly beneficial in environments where cabling and HVAC systems need to be easily accessible and adaptable.

Q: How does a steel raised access floor contribute to sustainability?

A: By decentralizing mechanical systems and allowing for efficient airflow management, steel raised access floors can reduce energy consumption in buildings. Additionally, they promote adaptability and longevity, minimizing the need for frequent renovations and thus contributing to a more sustainable built environment.

Q: Are there any drawbacks to using steel raised access floors?

A: While they offer significant benefits, there are potential drawbacks, including higher initial installation costs and the need for careful planning to ensure compatibility with existing systems. Additionally, the floor height might pose challenges in buildings with low ceilings or in spaces requiring a seamless transition.

Q: Can a steel raised access floor be customized?

A: Absolutely! Steel raised access floors come in various panel sizes, finishes, and load capacities, allowing for tailored solutions that meet the specific needs of a project. Optional features like anti-static materials, sound-absorption capabilities, and improves aesthetics also enhance customization.

Q: How do you maintain a steel raised access floor?

A: Maintenance is relatively straightforward. Regular inspections are recommended to ensure that panels are secure and that the space underneath remains clean and organized. Additionally, keeping cables and equipment neatly arranged not only improves safety but also facilitates easier access.

Q: What should businesses consider before choosing a raised access floor?

A: Businesses need to assess their current and future needs regarding technology infrastructure, space utilization, and design preferences. Conducting a cost-benefit analysis, evaluating the loading requirements, and considering the building’s layout are crucial for a successful installation.

Q: How does the installation process typically work?

A: The installation of a steel raised access floor generally involves several steps: site preparation, layout planning, pedestal placement, panel fitting, and finishing touches. It’s recommended to hire professionals with experience in this area to ensure the system is installed correctly and efficiently.

Through this Q&A, we hope to have provided clarity about steel raised access floors and their role in modern building design and infrastructure. Whether considering installation or simply wanting to learn more, understanding these systems can help facilitate informed decisions.

Final Thoughts

the steel raised access floor stands as a testament to innovative design in the realm of contemporary architecture and construction. By blending functionality with aesthetic appeal, these flooring systems not only facilitate seamless access to essential infrastructure but also empower spaces to adapt and evolve in response to the ever-changing demands of technology and human activity. Whether in data centers, office environments, or retail spaces, steel raised access floors offer a pragmatic solution that enhances usability while providing opportunities for creativity in design. As we continue to navigate the complexities of modern spaces, embracing such versatile systems will be vital in creating environments that are both efficient and adaptable, ensuring that our built world remains a reflection of our dynamic needs.